Sheet metal is a fundamental material used in various industries, characterized by its thin, flat Sheet Metal Parts pieces of metal. It can be made from various metals, including aluminum, steel, copper, brass, and titanium. The thickness of sheet metal typically ranges from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm), with thicker materials classified as plate metal.

Characteristics of Sheet Metal

Formability: Sheet metal can be easily shaped and formed into complex structures. This property makes it ideal for applications requiring intricate designs.

Strength: Despite its thinness, sheet metal is remarkably strong and durable, capable of withstanding significant stresses.

Versatility: Sheet metal can be used in a variety of applications, from automotive parts to construction elements.

Conductivity: Metals like aluminum and copper have excellent electrical and thermal conductivity, making them suitable for electrical components.

Manufacturing Processes for Sheet Metal Parts

Cutting: This is the initial step in sheet metal fabrication. Techniques include:

Shearing: A straight-cut process that uses blades.

Laser Cutting: A precise method using a high-powered laser.

Plasma Cutting: Utilizes ionized gas to cut through thick sheets.

Forming: This process involves bending or shaping the sheet metal to create desired geometries. Common forming techniques include:

Bending: Using presses to create angles and shapes.

Rolling: Forming sheets into cylindrical shapes.

Stamping: Using a die to create complex shapes.

Joining: Various methods are used to connect sheet metal parts, such as:

Welding: Fusing parts together using heat.

Riveting: Using metal fasteners to hold parts together.

Adhesive Bonding: Using adhesives for a strong bond without heat.

Finishing: This step enhances the appearance and durability of the metal. Finishing techniques include:

Painting: Adds a protective layer and improves aesthetics.

Plating: Depositing a layer of metal to improve corrosion resistance.

Anodizing: An electrochemical process that increases thickness of the natural oxide layer.

Applications of Sheet Metal Parts

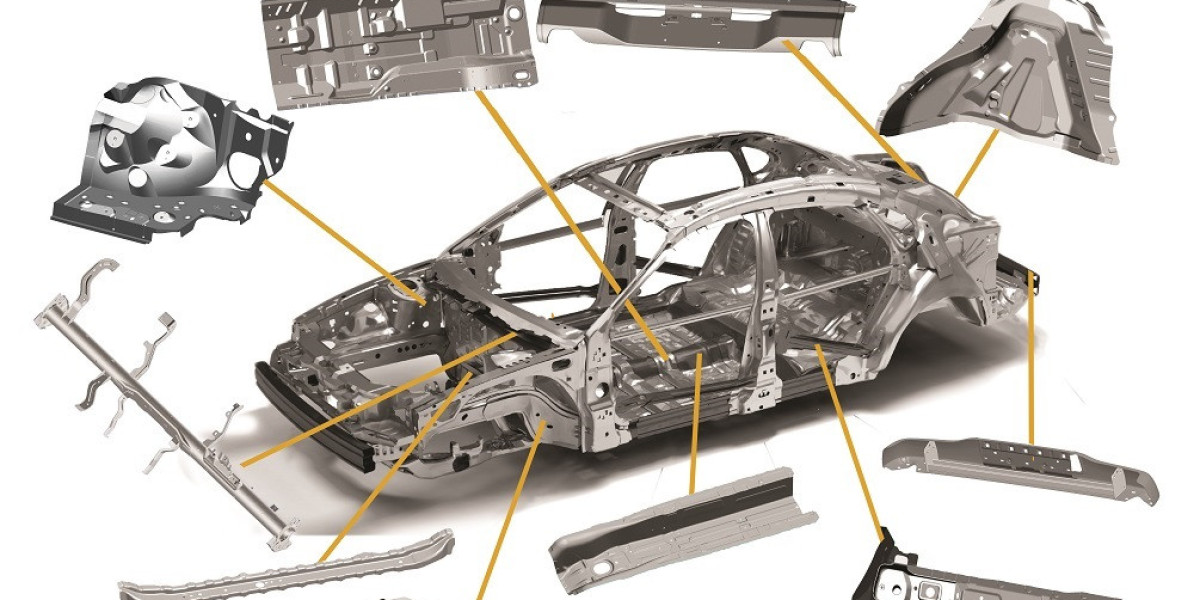

Automotive: Used for body panels, chassis components, and interior parts.

Aerospace: Critical for aircraft structures and components, where weight and strength are paramount.

Construction: Utilized in roofing, siding, and HVAC systems.

Electronics: Found in enclosures, heat sinks, and circuit boards.

Appliances: Common in the manufacturing of refrigerators, ovens, and washing machines.

Advantages of Sheet Metal Parts

Cost-Effectiveness: Sheet metal is relatively inexpensive to produce and work with.

Lightweight: Reduces overall weight without sacrificing strength, beneficial for automotive and aerospace applications.

Customization: Easily tailored to specific needs through various fabrication techniques.

Recyclability: Metals can be recycled, making sheet metal a sustainable choice.

Challenges in Sheet Metal Fabrication

Thickness Limitations: Some processes may not be suitable for very thick sheets.

Precision Requirements: Maintaining tight tolerances can be challenging, especially in complex designs.

Material Properties: Different metals have unique properties that can affect the choice of fabrication methods.

Conclusion

Sheet metal parts play a vital role in a multitude of industries due to their versatility, strength, and ease of fabrication. Understanding the various processes and applications of sheet metal can help businesses and engineers make informed decisions when designing and manufacturing components. As technology advances, the capabilities of sheet metal fabrication continue to expand, opening new avenues for innovation and efficiency.